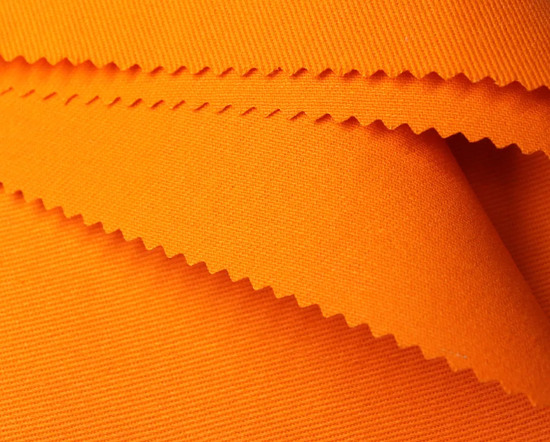

Regarding the manufacturing materials of fire resistant clothing, it is easy for us to think of flame resistant fabrics, which are a type of special fabric with flame resistant properties and are often used in the production of protective workwear, transportation interiors, decorative materials, and some special environments.

The manufacturing of fire resistant clothing uses a large amount of flame resistant fabrics, including hoods, jackets, pants, gloves, and protective feet. High-quality fire suits have the characteristics of high temperature resistance, flame retardancy, heat radiation resistance, water resistance, wear resistance, folding resistance, light weight, and harmlessness to the human body, which can effectively protect firefighters or workers in high-temperature environments from being burned by extreme heat, flames, or steam.

The quality of fire resistant clothing is directly related to the quality of the manufacturing materials, so choosing high-quality flame resistant fabrics is the key.

What are flame resistant fabrics?

Flame resistant fabrics are a type of fabric that can prevent itself from being ignited or delay and terminate the combustion of flames when in contact with flames or hot objects. It is suitable for environments with open flames, spark emissions, or molten metals, and plays a role in protecting workers; as well as in environments with flammable, explosive substances, or fire hazards, and plays a protective role.

Kinds of fire retardant fabrics

Fire retardant fabrics are divided into inherently flame resistant fabrics and flame retardant treated fabrics.

Inherently flame resistant fabrics

Inherently flame resistant means that the fibers themselves have permanent flame retardancy, and these flame retardant fibers also have excellent electrical insulation, heat resistance, and wear resistance. For example, aramid, modified acrylic, PSA, phenolic fibers, etc., these inherently flame retardant fibers can provide excellent fire and heat protection.

Aramid

Aramid is a type of synthetic fiber with permanent flame retardancy, heat resistance, high strength, high wear resistance, good flexibility, low shrinkage, stable chemical structure, no melting droplets during combustion, and no toxic gas generation.

Aramid fiber fabrics are not only used to make aramid fire resistant clothing, but also are often used as military materials, and bulletproof vests in developed countries are all made of aramid. In addition, aramid fibers, as a high-tech fiber material, are widely used in aerospace, electromechanical, construction, automotive, sports goods, and other fields.

Modified acrylic

Modified acrylic is a type of artificial flame retardant fiber, mainly made from polyacrylonitrile (PAN) after modification treatment, which itself has flame retardancy and can be pure-spun or blended with cotton, wool, viscose, antistatic fibers, etc. to form a variety of flame retardant acrylic fabrics with different styles, and the blending ratio of acrylic and cotton can also be adjusted according to needs to achieve different flame retardant levels.

The modified acrylic flame retardant fabric has a soft and elastic texture, a fluffy and wool-like feel, and good warmth retention. The protective workwear made from it has been widely used in the petroleum, chemical, electric power, or gas industries.

PSA

PSA fiber, is composed of polysulfonamide. PSA has excellent flame retardancy, electrical insulation, and heat resistance. In addition to slightly lower strength, other properties are similar to aramid fibers, but it is significantly superior to aramid fibers in terms of fire resistance and thermal oxidative aging. It is mainly used to make high-grade flame retardant fabrics, fire resistant clothing, fire-resistant workwear, high-temperature filter materials, etc.

Phenolic fibers

Phenolic fibers are made from phenolic resins through the processes of spinning and curing crosslinking. This type of flame retardant fiber has superior thermal insulation properties and the ability to withstand instantaneous high temperatures, combining multiple functions such as flame retardancy, insulation, high temperature resistance, corrosion resistance, and sound insulation. Phenolic fiber fabrics are suitable for making fire-resistant workwear, anti-corrosion clothing, acid and corrosion-resistant filter materials, and flame retardant decorative materials.

Flame retardant treated fabrics

Flame retardant treated fabrics refer to the chemical modification or flame retardant treatment of ordinary textiles(to make the flame retardant fixed on the fabric or yarn to obtain the flame retardant effect), so that the fabric has the functions of heat insulation and flame retardancy. Common fabrics such as cotton fabrics, polyester fabrics, cotton-polyester blended fabrics, nylon fabrics, acrylic fabrics, and wool fabrics can all achieve corresponding flame retardant properties through flame retardant treatment, and their fire resistance and heat resistance can also be very excellent.

The advantage of flame retardant treated fabrics is that the process is simple and the cost is low, which can widely meet the requirements of different flame retardant levels and fire resistance grades. It is worth noting that due to different treatment processes, the flame retardant performance of some types of flame retardant treated fabrics may decrease or disappear after multiple washes or abrasions.

How to choose flame retardant fabric materials?

When choosing flame retardant materials, the first step is to clearly define the usage environment and specific purpose. Different environments and purposes have different requirements for flame retardant levels and fire resistance grades, as well as different performance requirements for flame retardant materials. For example, the flame retardant fabric indicators and requirements for fireproof suits and flame retardant curtains are completely different. In addition to flame retardancy indicators, flame retardant protective clothing also needs to consider the comfort and wear resistance of the workers wearing it, which will affect the production cost of flame retardant fabrics. Therefore, only after clarifying the usage environment and specific purpose can it be confirmed which flame retardant fabric is most suitable as the manufacturing material.

How to judge the flame retardant performance of flame retardant fabrics?

There are usually two methods to judge the flame retardant performance of flame retardant fabrics:

- Evaluate based on the burning rate of the fabric.

That is, the flame-retardant fabric is exposed to the flame for a certain period of time according to the specified method, and then the flame is removed to measure the time of continued flaming and non-flaming combustion of the fabric, as well as the degree of damage to the fabric. The shorter the time of flaming and non-flaming combustion, and the lower the degree of damage to the flame retardant fabric, the better the flame retardant performance of the fabric; conversely, the poorer the flame retardant performance of the flame retardant material.

- Evaluate by measuring the limiting oxygen index of the sample.

The limiting oxygen index (LOI) is a description of the amount of oxygen required for the combustion of flame retardant materials, and the flame retardant performance of flame retardant fabrics can be determined by measuring the oxygen index. The higher the oxygen index, the higher the oxygen concentration required to maintain combustion, which means it is more difficult to burn.

The LOI index can be expressed as the minimum volume percentage of oxygen required to maintain a candle-like combustion of the sample in a nitrogen-oxygen gas mixture. Theoretically, as long as the oxygen index of textile materials is greater than 21% (the volume concentration of oxygen in the natural air), it has self-extinguishing properties in the air.

According to the size of the oxygen index, textiles can usually be divided into four grades:

- Flammable (LOI<20%)

- Combustible (LOI=20%~26%)

- Difficult to burn (LOI=26%~34%)

- Non-flammable (LOI>35%)

Conclusion

There are many types of raw materials for making flame retardant fabrics, and different raw materials have their own advantages and disadvantages. These factors should be fully considered when choosing flame retardant fabric materials. In many cases, the requirements for fire resistant clothing may not only be simple heat insulation and fire resistance, but also the specific usage environment and purpose must be combined to confirm how to choose flame retardant materials. For example, in addition to fire insulation, is arc resistance also required? Is protection against molten metal splashes also required? The comfort, durability, color, and style of the protective clothing are also considerations.

More suggestions

We are a professional flame retardant fabric supplier with extensive experience in this field. We understand the importance of safety in various industries, so we adhere to strict production safety standards to ensure that customers receive high-quality flame retardant fabrics while maintaining competitive prices.

If you have any questions, please contact us immediately or request a quote. Our professional research team can customize special or new types of flame retardant fabrics for customers.

Contact us: [email protected]